The Ultimate Showdown: MDF or WPC Wall Panels?

Hello there, fellow enthusiasts of interior design and home improvement! Today, we're diving into the fascinating world of wall paneling to explore the key differences between two popular options: WPC (Wood Plastic Composite) and MDF (Medium-Density Fiberboard). Whether you're a homeowner looking to spruce up your living space or a professional seeking the perfect material for your next project, understanding these distinctions will empower you to make an informed decision. So, let's embark on this journey of discovery and unravel the unique characteristics of WPC wall panels.

What is MDF and what is it made of?

MDF stands for Medium-Density Fiberboard. It is a type of engineered wood product that is widely used in construction, furniture manufacturing, and interior design. MDF is made from wood fibers that are combined with a synthetic resin binder and formed into panels under high temperature and pressure.

The resulting MDF panels have a smooth and consistent surface, without the natural grain patterns or knots found in solid wood. This makes MDF a versatile material for various applications, as it can be easily painted, laminated, or veneered to achieve different finishes and aesthetics.

The composition of MDF panels can vary depending on the manufacturing process and specific product requirements. However, in general, MDF is made up of approximately 82% wood fibers and 18% resin binder by weight. The wood fibers used in MDF production can come from both virgin and recycled sources, making it a potentially sustainable option when using recycled wood fibers.

It's worth noting that MDF contains a resin binder, which typically includes formaldehyde-based adhesives. Formaldehyde emissions can be a concern in some MDF products, especially those produced with lower-quality or less-regulated manufacturing processes.

What is WPC wall panel and what is it made of?

WPC wall panel, also known as wood-plastic composite siding, is a wall covering that combines wood fibers and thermoplastics to create a durable and versatile product. WPC wall panels are used in both residential and commercial settings for their aesthetic and functional advantages.

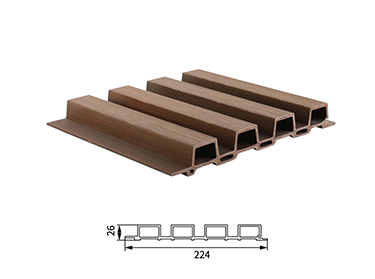

WPC wall panel is typically made from a blend of wood fibers and plastic materials such as polyethylene (PE), polypropylene (PP) or polyvinyl chloride (PVC). The wood fiber used in WPC wall panel comes from a variety of sources including sawdust, wood chips or agricultural residues. These wood fibers are mixed with plastic materials and other additives such as colorants, UV stabilizers.

The manufacturing process of WPC wall panels involves combining the wood fibers and plastic materials through a process called extrusion. In this process, the mixture is heated and Pressurized and push by an extrusion screw, which melts the plastic and evenly distributes it among the wood fibers. The molten mixture is then shaped into panels of the desired size and thickness using specialized molds.

The combination of wood fiber and plastic materials in WPC wall panel offers several advantages. First, WPC wall panel has the natural look and feel of wood for visual appeal that complements a variety of interior and exterior design styles. WPC wall panels are less prone to warping, cracking and fading, making them suitable for both indoor and outdoor applications.

Additionally, WPC wall panel is known for being low maintenance. WPC wall panel does not require regular painting, staining or sealing to maintain its appearance and durability. WPC wall panels are easy to clean, just wipe with a damp cloth or use a mild detergent for maintenance.

Overall, WPC wall panels offer a sustainable and durable alternative to traditional wall cladding materials. They combine the best of both wood and plastic, combining the natural beauty of wood with the enhanced performance and longevity of plastic materials. Widely used in residential and commercial construction projects, WPC wall panels provide an attractive and practical solution for enhancing the aesthetics and functionality of interior and exterior walls.

What are the advantages and disadvantages of MDF?

Advantages of MDF:

Affordability: MDF is generally more affordable compared to solid wood or other engineered wood products, making it a cost-effective option for various applications.

Smooth and Uniform Surface: MDF has a smooth and uniform surface, which makes it ideal for painting, veneering, or laminating. It provides a consistent finish without the natural grain patterns or knots found in solid wood.

Versatility: MDF can be easily shaped, cut, routed, and drilled, allowing for intricate and customized designs. It is commonly used in cabinetry, furniture, shelving, and other woodworking projects.

Disadvantages of MDF:

Susceptible to Moisture Damage: MDF is susceptible to moisture damage and can swell or warp if exposed to excessive moisture. It is not recommended for use in areas with high humidity or where it may come into direct contact with water.

Low Strength and Durability: While MDF is dense and strong for its weight, it is not as strong or durable as solid wood. It may not be suitable for applications that require heavy load-bearing or high impact resistance.

Limited Screw Holding Capacity: MDF has lower screw holding capacity compared to solid wood, which means it may not provide the same level of support or holding power for screws and fasteners.

Formaldehyde Emissions: Some MDF products may emit formaldehyde, a volatile organic compound (VOC), especially those made with urea-formaldehyde adhesives. However, there are low-emission and formaldehyde-free options available in the market.

Difficult to Repair: MDF is more difficult to repair compared to solid wood. It is prone to chipping or denting, and once damaged, it can be challenging to restore its original appearance.

What are the advantages and disadvantages of WPC wall panel?

Advantages of WPC Wall Panels:

Durability: WPC wall panels are known for their exceptional durability. They are made of a combination of wood fibers and plastic polymers, resulting in a strong and resilient material. WPC panels can withstand various environmental conditions, including moisture, humidity, and temperature changes, without warping, cracking, or rotting.

Low Maintenance: WPC wall panels are virtually maintenance-free. They do not require regular painting, staining, or sealing like traditional wood panels. WPC panels are resistant to fading, staining, and mold growth, making them easy to clean and maintain. A simple wash with soap and water is usually sufficient to keep them looking pristine.

Versatility: WPC wall panels offer versatility in terms of design and style. They can be manufactured in various colors, finishes, and textures, allowing homeowners and designers to achieve the desired aesthetic for their interior or exterior spaces. WPC panels can mimic the appearance of natural wood, providing a warm and inviting ambiance.

Eco-Friendly: WPC wall panels are considered environmentally friendly due to their use of recycled materials. The combination of wood fibers and plastic polymers helps reduce the consumption of natural wood resources. Additionally, WPC panels are recyclable, further contributing to sustainable practices.

Moisture Resistance: One of the significant advantages of WPC wall panels is their resistance to moisture. Unlike traditional wood panels, WPC panels do not absorb moisture, which helps prevent issues such as swelling, warping, or rotting. This makes them suitable for areas prone to high humidity, such as bathrooms and kitchens.

Disadvantages of WPC Wall Panels:

Color fading: When WPC wall panel is exposed to ultraviolet light for a long time, the normal WPC wall panel will change its original color,so when choosing WPC wall panel, choose a manufacturer with co-extrusion technology, because this a technology is equivalent to forming a protective film for the WPC wall panel, which has a certain ability to protect against long-term ultraviolet radiation.

MATECO’s wall panel products has been updated to the 2nd-Gen Co-Extrusion tech which enable the us to guarantee that the indoor WPC wall panel will not fade or deform for 20 years, and the outdoor WPC wall panel will not fade or deform for 10 years.

Price: WPC wall panels may have a higher upfront cost compared to traditional wood panels. However, considering their long-term durability, low maintenance requirements, and resistance to environmental factors, the overall cost-effectiveness of WPC panels becomes evident.

Compared with other wall panels, the unit price of WPC wall panel is relatively high, but the wall panel is not a consumable, the price of the wall panel cannot be determined by the unit price, more is to consider the cost and time of later maintenance, click on the picture below, Find out about the subsequent costs of wpc wall panels.

Installation Considerations: Installing WPC wall panels may require specific tools and techniques, especially if complex cuts or installations are involved. It is recommended to hire professional technicians or follow the manufacturer's guidelines to ensure proper installation and optimal performance.

For the installation of WPC wall panel, if you don’t know how to install it, you can rest assured that MATECO has a professional team and services that satisfy you, guaranteeing all kinds of teaching and services.

Conclusion

To sum up, both WPC wall panel and MDF wall panel have their own distinct advantages. WPC wall panels offer excellent moisture resistance, durability, and a variety of design options. MDF panels, on the other hand, are highly regarded for their affordability, consistent quality, and versatility. By understanding the key differences between these two materials, you can confidently choose the siding solution that best meets your project requirements, budget and personal style.

Keep in mind that when exploring the world of wall panels, WPC wall panels are an excellent choice for those looking for long-lasting durability, moisture resistance, and limitless design possibilities and when it comes to choosing a supplier of WPC products, we have always been dedicated to provide superior WPC products worldwide.