Is WPC Exterior Wall Cladding Really Mold Resistant?

A key question often faced by homeowners and builders alike: Is WPC exterior wall cladding truly mold resistant? If you've been considering this innovative building material for your next project or wondering about its suitability for your home, you're in the right place.

In this article, we'll leave no stone unturned as we delve into the world of WPC (Wood-Plastic Composite) exterior wall cladding. We'll explore the importance of mold resistance in exterior cladding, examining why it's a topic of growing concern among homeowners. Along the way, we'll shine a light on various aspects of this fascinating material, covering topics such as its features, comparative analysis with other materials, and expert insights.

1. What is WPC exterior wall cladding?

Wood-Plastic Composite (WPC) Exterior Wall Cladding is a modern, innovative building material that has been gaining increasing popularity in the construction industry. It is a versatile and sustainable alternative to traditional siding materials like wood, vinyl, or fiber cement. WPC cladding is engineered to combine the best qualities of wood and plastic while minimizing their respective drawbacks.

MATECO WPC offers wood-plastic composite exterior wall cladding panels made from a blend of wood and plastic materials.

MATECO WPC co-extrusion exterior wall cladding

One of the key reasons behind the growing popularity of WPC cladding is its exceptional durability. Unlike traditional wood siding, WPC cladding doesn't warp, crack, or splinter, even in harsh weather conditions. It is also resistant to fading and color changes, maintaining its aesthetic appeal over time. This durability translates into a longer lifespan for the cladding, reducing maintenance and replacement costs for homeowners and builders.

Moreover, WPC cladding is known for its low maintenance requirements. It doesn't need to be stained, sealed, or painted regularly like wood siding, saving both time and money. A simple cleaning with soap and water is typically sufficient to keep it looking pristine. This ease of maintenance makes it an attractive option for homeowners who appreciate the beauty of wood without the hassle of extensive upkeep.

Another significant advantage of WPC exterior wall cladding is its sustainability. By utilizing recycled wood fibers and reducing the demand for virgin wood, WPC contributes to the preservation of forests. Its long lifespan also means fewer replacement materials are needed, reducing waste.

2. The Importance of Mold Resistance in Cladding

Mold resistance is a crucial factor to consider when choosing exterior wall cladding materials, and it matters for several compelling reasons. First and foremost, mold can wreak havoc on the structural integrity of a building. When mold takes root in cladding materials, it can lead to rot and decay, weakening the very foundation of a structure. This deterioration not only compromises the safety of the building but also results in costly repairs and replacements. Therefore, selecting cladding that is resistant to mold is a proactive step in preserving the long-term durability of your property.

Beyond structural concerns, mold resistance is essential for maintaining the aesthetic appeal of your home or building. Mold growth on exterior cladding is unsightly and can lead to staining, discoloration, and an overall dingy appearance. These cosmetic issues can negatively impact curb appeal, property value, and the impression your building makes on visitors or potential buyers. By choosing mold-resistant cladding, you not only protect your investment but also ensure that your property maintains its visual charm over time.

Mold resistance is not just a matter of appearances; it's also about the health and well-being of those who inhabit the building. Mold spores can become airborne and infiltrate indoor spaces, leading to a host of health problems, especially for individuals with allergies or respiratory issues. Symptoms can include coughing, sneezing, skin irritation, and even more severe respiratory conditions. By opting for mold-resistant cladding, you create a healthier indoor environment, reducing the risk of mold-related health concerns for occupants.

Composite Wall Cladding for Office Building

3. WPC Cladding vs. Mold

Wood-plastic composite (WPC) cladding has gained a reputation for being an excellent choice for exterior applications, in no small part due to its impressive resistance to mold growth. Mold is a persistent threat to exterior cladding, particularly in regions with high humidity or frequent rain. However, WPC cladding stands out as a formidable adversary against the mold menace.

One of the primary reasons for WPC cladding's resistance to mold is its composition. Unlike traditional wood, which is an organic material that mold spores can readily feed on, WPC combines wood fibers with plastic resins. By encapsulating the wood fibers within a protective plastic shell, WPC cladding effectively eliminates the organic material mold needs to thrive.

Additionally, the plastic component of WPC cladding, typically made of high-density polyethylene (HDPE) or polyvinyl chloride (PVC), offers natural resistance to moisture and decay. Mold requires moisture to grow, and WPC's inherent resistance to water absorption makes it an inhospitable environment for mold spores. As a result, WPC cladding remains unfazed by the damp conditions that might encourage mold growth in other materials.

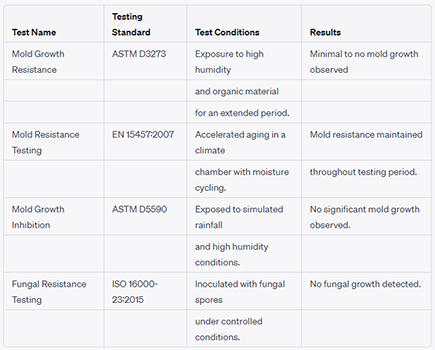

Furthermore, WPC cladding often undergoes rigorous testing to ensure its mold resistance. These tests evaluate its ability to resist mold growth under various conditions, such as exposure to moisture, temperature fluctuations, and organic materials. The results consistently demonstrate that WPC cladding is an effective deterrent against mold, maintaining its appearance and structural integrity even in challenging environmental conditions.

WPC Cladding Mold Resistance Testing Result

4. Exploring WPC Cladding's Mold-Resistant Qualities

Mold resistance is a standout feature of WPC (Wood-Plastic Composite) exterior wall cladding, and understanding the specific characteristics that contribute to this resistance is crucial for homeowners and builders. Here, we'll explore the key mold-resistant features that make WPC cladding a reliable choice for exterior applications.

1) Composite Composition: The core of WPC cladding consists of a blend of wood fibers or flour and plastic resins. This composition is where the magic happens when it comes to mold resistance. Unlike solid wood, which provides an ideal food source for mold spores, the wood component in WPC is encapsulated within the plastic. This encapsulation creates a protective barrier that inhibits mold growth. Mold needs organic material to thrive, and WPC denies it access to the wood fibers, effectively preventing mold colonization.

2) Moisture Resistance: Moisture is a primary catalyst for mold growth. WPC cladding's inherent resistance to moisture absorption is a significant factor in its mold resistance. High-quality WPC cladding is designed to repel moisture, making it unfavorable for mold spores to establish a foothold. Even in wet or humid climates, WPC cladding maintains its integrity and mold resistance over time.

3) No Cracks or Crevices: Traditional cladding materials like wood or vinyl often have seams, joints, or textured surfaces where moisture can collect and mold can take hold. In contrast, WPC cladding typically features a smooth, seamless surface that leaves no room for mold to hide. This uniformity, combined with its mold-resistant composition, makes it an uninviting environment for mold growth.

4) Low Maintenance: Mold can flourish on surfaces that are difficult to clean or maintain. WPC cladding's low-maintenance nature simplifies the task of keeping it mold-free. Regular cleaning with mild soap and water is usually sufficient to preserve its mold resistance. The absence of the rigorous maintenance required by wood siding, such as staining or sealing, reduces the risk of mold gaining a foothold.

5) Durability: The durability of WPC cladding is another mold-resistant feature worth noting. Unlike materials that may degrade over time due to moisture exposure, WPC cladding remains robust and structurally sound. This durability not only enhances its longevity but also ensures that it maintains its resistance to mold throughout its lifespan.

Composite Wall Cladding For Swimming Pool

5. Maintenance Tips for Composite Wood Cladding

Regular Cleaning: Keeping your WPC cladding clean is the first line of defense against mold growth. Fortunately, WPC is relatively low maintenance. You can maintain its mold-resistant properties by regularly cleaning it with a solution of mild soap and water. This simple cleaning routine helps remove dirt, dust, and potential organic materials that can accumulate on the surface and create conditions favorable for mold. A soft brush or sponge is usually sufficient for this task. Be sure to rinse thoroughly with clean water to remove all soap residue. Avoid abrasive cleaners or harsh chemicals, as they can damage the surface and compromise the cladding's appearance and resistance to mold.

Conclusion:

MATECO WPC is the leading composite wall panel manufacturer in China. By choosing WPC cladding, you not only enhance the aesthetics of your building but also ensure its long-term durability and the well-being of those who inhabit it. The battle against the mold menace is a crucial one, and with WPC cladding as your ally, you can face this challenge with confidence. So, whether you're embarking on a new construction project or considering a renovation, remember that with WPC exterior wall cladding, you're not just investing in a beautiful facade; you're investing in a mold-resistant, low-maintenance, and long-lasting solution that stands the test of time.

If you are looking for a WPC manufacturer, MATECO WPC will be your best choice.

Website: https://www.matecowpc.com

WhatsApp: +86-13380085620

Email: info@matecowpc.com